Contents

AI in Manufacturing refers to the integration of artificial intelligence technologies into various aspects of production, from optimising factory floor operations and predictive maintenance to automating quality control and personalising product design, ultimately aiming to boost efficiency, reduce costs, and drive innovation in the manufacturing sector.

What is AI in Manufacturing?

Artificial Intelligence (AI) is rapidly transforming the manufacturing landscape. By integrating AI into various aspects of production, companies are achieving greater efficiency, improved quality control, and a significant boost in productivity. Here’s how AI is making its mark in manufacturing:

Intelligent Automation:

AI is taking automation in manufacturing to a whole new level. Automated assembly lines are becoming smarter, with AI-powered robots performing complex tasks with greater precision and adaptability. This not only reduces human error but also enables faster production cycles.

Predictive Maintenance:

AI in manufacturing allows for the implementation of predictive maintenance strategies. By analysing sensor data from machines, AI can anticipate potential equipment failures before they occur. This proactive approach minimises downtime and maintenance costs, ensuring smooth operation of manufacturing systems.

Quality Control with a Digital Eye:

AI-powered vision systems are revolutionising quality control. These systems can inspect products with superhuman precision and consistency, identifying even the smallest defects that might escape human inspection. This significantly improves overall product quality and reduces waste.

The Rise of Automotive AI:

The automotive industry is a prime example of AI’s impact on manufacturing. Automotive AI is driving advancements in self-driving cars, robotic welding, and automated paint processes. AI algorithms are optimising every step of the production line, leading to faster turnaround times and higher quality vehicles.

Overall, AI in manufacturing is creating a future of intelligent automation, predictive maintenance, and enhanced quality control. This integration of AI and machine learning development is transforming factories into interconnected ecosystems where machines learn, adapt, and optimise production processes, paving the way for a new era of intelligent manufacturing.

The Role of AI in Manufacturing Industry:

The manufacturing industry is undergoing a revolution driven by Artificial Intelligence (AI). AI is rapidly transforming every aspect of production, from design and planning to execution and quality control. Here’s a glimpse into how AI is reshaping the landscape:

Smarter Automation:

Repetitive tasks on assembly lines are being taken over by intelligent robots powered by automotive AI. These robots can learn, adapt, and perform complex tasks with high precision, significantly boosting efficiency and production speed.

AI is transforming entire manufacturing systems. Production lines are becoming self-optimising, with data analytics from sensors and machines to identify bottlenecks, predict equipment failures, and adjust processes in real-time. This level of automation in manufacturing minimises downtime and ensures consistent product quality.

Enhanced Design & Planning:

AI algorithms are assisting engineers in product design. These tools can analyse vast amounts of data to optimise product functionality, identify potential issues early on, and even generate creative design concepts.

AI is revolutionising production planning. By using data engineering services for historical data and market trends, AI can forecast demand and optimise production schedules, ensuring factories have the right materials and resources available at the right time. This reduces waste and optimises resource allocation within manufacturing systems.

Improved Quality Control & Maintenance:

Machine vision powered by AI is transforming quality control. AI systems can inspect products with superhuman accuracy and consistency, detecting even the slightest defects that might escape human inspectors.

AI algorithms are being used for predictive maintenance. By analysing sensor data from machinery, AI can predict potential equipment failures before they occur, allowing for proactive maintenance and preventing costly downtime.

The integration of AI into manufacturing is not just about replacing human workers. Instead, it’s about creating a collaborative environment where humans and machines work together to achieve new levels of efficiency, precision, and innovation. As automation in manufacturing powered by AI continues to evolve, the future of this industry promises to be one of remarkable transformation and growth.

Applications of AI in Production Planning and Scheduling:

The rise of artificial intelligence (AI) is transforming the manufacturing landscape, particularly in production planning and scheduling. Here’s how AI is making waves in this critical area:

Enhanced Demand Forecasting:

AI can analyse vast amounts of historical sales data, market trends, and external factors to predict demand with exceptional accuracy. This empowers manufacturers to plan production runs more effectively, reducing the risk of stockouts or excess inventory.

Optimised Scheduling for Efficiency:

AI algorithms can analyse complex production processes, considering factors like machine capabilities, material availability, and labour requirements. This allows for the creation of highly optimised schedules that minimise idle time and maximise throughput in automated assembly lines and manufacturing systems.

Predictive Maintenance with Automotive AI:

AI can monitor sensor data from machines on the factory floor, identifying potential issues before they escalate into costly breakdowns. This proactive approach to maintenance, powered by automotive AI, helps ensure smooth operation and prevents disruptions in production schedules.

Real-time Adjustments and Adaptability:

Automation in manufacturing is no longer rigid. AI allows for real-time adjustments to production schedules in response to unexpected events. This could include machine breakdowns, supply chain disruptions, or sudden changes in demand. AI can quickly re-optimise schedules to minimise impact and maintain production efficiency

Improved Resource Allocation:

AI can analyse data on labour, materials, and machine capabilities to ensure the most efficient allocation of resources across the production process. This not only optimises production but also minimises waste and keeps costs in check.

By leveraging these applications of AI, manufacturers can achieve significant improvements in production planning and scheduling. This translates to increased efficiency, reduced costs, and a more agile and responsive production system that can adapt to the ever-changing demands of the market.

Predictive Maintenance for Preventing Downtime with Automated Assembly Line:

In today’s industrial landscape, where efficiency and productivity reign supreme, downtime can be a costly nightmare. This is especially true in the realm of manufacturing, where automated assembly lines and manufacturing systems power production. Predictive maintenance, fueled by the power of automotive AI, offers a revolutionary approach to preventing downtime before it occurs.

Traditional maintenance relies on scheduled inspections or reacting to breakdowns. Predictive maintenance, however, takes a proactive stance. By leveraging sensors embedded within machinery and manufacturing systems, AI collects real-time data on equipment performance. This data includes vibration, temperature, and energy consumption.

Here’s where automotive AI shines. AI algorithms analyse this vast data stream, identifying subtle patterns and anomalies that might signal a potential equipment failure. This allows for early intervention, enabling technicians to address minor issues before they snowball into major breakdowns.

The benefits of predictive maintenance with AI are numerous. Automated assembly lines and manufacturing systems can operate with increased uptime, minimising production delays and lost revenue. Additionally, parts replacements can be strategically planned, reducing the need to keep excessive spare parts inventory.

Furthermore, predictive maintenance with AI fosters a data-driven approach to maintenance. This empowers manufacturers to optimise maintenance schedules, focusing resources on equipment most likely to experience problems. Automotive AI is transforming the way we maintain industrial machinery, paving the way for a future of maximised uptime and optimised production within the realm of automation in manufacturing.

Quality Control and Inspection Automation Using AI:

The manufacturing industry is undergoing a transformative shift with the integration of Artificial Intelligence (AI). One of the most impactful areas is quality control and inspection. Automation in manufacturing is no longer a futuristic concept, and AI is playing a leading role in this transformation.

Traditional quality control methods often rely on manual inspections, which can be time-consuming, prone to human error, and inconsistent. Automotive AI is revolutionising this process by enabling automated assembly line inspections with unmatched precision and efficiency. Here’s how AI is driving automation in manufacturing systems for quality control:

Machine Vision and AI Integration:

AI algorithms are coupled with high-resolution cameras to analyse product images in real-time. This allows for the detection of even the most subtle defects that might escape human inspectors.

Predictive Maintenance:

By analysing sensor data from manufacturing systems, AI can predict potential equipment failures before they occur. This proactive approach minimises downtime and ensures consistent product quality.

Self-Learning and Adaptability:

AI-powered quality control systems can continuously learn and improve over time. They can adapt to variations in product design or manufacturing processes, ensuring consistent quality throughout production runs.

The benefits of quality control and inspection automation using AI extend far beyond improved accuracy. Automotive AI applications can significantly improve:

Production Efficiency:

Automating inspections frees up human workers for higher-value tasks, leading to faster production cycles.

Reduced Costs:

Early defect detection minimises product waste and rework, ultimately reducing overall production costs.

Data-Driven Decision-Making:

AI systems generate valuable data on production processes and product quality. This data can be used to identify areas for improvement and optimise manufacturing systems.

The integration of AI in quality control and inspection represents a significant leap forward in automation in manufacturing. By leveraging AI’s capabilities, manufacturers can achieve higher quality standards, improve efficiency, and gain a significant competitive edge.

Robotics and Automation in Manufacturing by AI-driven Solutions:

The manufacturing industry is undergoing a significant transformation driven by the integration of robotics, automation, and artificial intelligence (AI). This powerful combination is revolutionising production processes, leading to increased efficiency, accuracy, and flexibility.

Gone are the days of simple, pre-programmed robots. Automotive AI is enabling robots to become more intelligent and adaptable. These robots can learn from their experiences on the automated assembly line, continuously improving their performance and decision-making capabilities. This allows for real-time adjustments based on production data, optimising processes, and minimising errors.

The rise of automation in manufacturing is not new, but AI is taking it to a whole new level. Manufacturing systems are becoming more sophisticated, capable of handling complex tasks with greater precision and speed. AI-powered vision systems can inspect products for defects with unmatched accuracy, while intelligent robots can handle delicate and intricate assembly processes.

The advantages of AI-driven robotics and automation in manufacturing are numerous. Production lines become more efficient, leading to increased output and reduced costs. Automated assembly lines can operate 24/7 with minimal human intervention, maximising production uptime. Additionally, AI can optimise resource allocation and energy consumption within manufacturing systems.

Looking ahead, the future of manufacturing is undoubtedly intertwined with AI-powered robotics and automation. As AI technology continues to evolve, we can expect even smarter robots, more sophisticated automation systems, and a new era of intelligent manufacturing that is efficient, precise, and adaptable to meet the ever-changing demands of the industry.

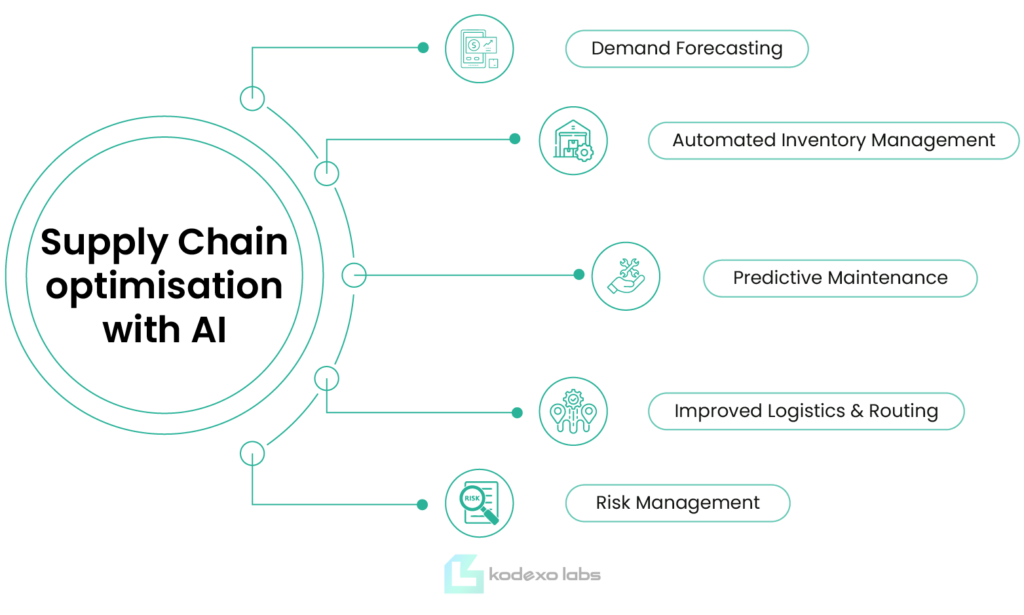

Supply Chain Optimization with AI:

The world of manufacturing is undergoing a transformation driven by artificial intelligence (AI). In the realm of supply chains, AI is emerging as a powerful tool for optimisation, leading to increased efficiency, reduced costs, and improved responsiveness. Here’s how AI is reshaping supply chain management:

Demand Forecasting:

AI algorithms can analyse vast amounts of historical sales data, market trends, and social media sentiment to predict future demand with remarkable accuracy. This empowers manufacturers to optimise production schedules, inventory levels, and resource allocation, preventing stockouts and overproduction.

Automated Inventory Management:

AI can monitor inventory levels in real-time, automatically triggering reorders when supplies dwindle. This eliminates the need for manual stock checks and ensures a steady flow of materials for automated assembly lines within automated manufacturing systems.

Predictive Maintenance:

AI can analyse sensor data from machines to predict potential equipment failures before they occur. This proactive approach to maintenance helps prevent costly downtime and ensures the smooth operation of automation in manufacturing.

Improved Logistics & Routing:

AI can optimise transportation routes, considering factors like traffic patterns, weather conditions, and fuel efficiency. This leads to faster delivery times, reduced transportation costs, and a more sustainable supply chain.

Risk Management:

AI can analyse market data, weather forecasts, and geopolitical events to identify potential disruptions in the supply chain. This allows manufacturers to develop contingency plans and mitigate risks proactively, ensuring a resilient and adaptable operation in the face of unforeseen challenges.

The AI integration into automotive AI is a prime example. Imagine an intelligent system optimising parts delivery for automated assembly lines within a car factory. By predicting demand and potential disruptions, AI ensures a smooth flow of materials, maximising production efficiency.

Overall, supply chain optimisation with AI is transforming the manufacturing landscape. By leveraging AI’s analytical power, manufacturers can gain a significant competitive edge, achieving greater efficiency, agility, and responsiveness in a dynamic global market.

Smart Manufacturing for Integrating IoT and AI for Real-time Insights:

The future of manufacturing is smart, driven by the powerful duo of the Internet of Things (IoT) and Artificial Intelligence (AI). This integration unlocks a new era of real-time insights, propelling efficiency and productivity to unseen heights.

The Intelligent Core of Automation:

Once collected, the vast amount of data is fed into AI algorithms. Here, automotive AI and other specialised AI models come into play. These intelligent systems analyse the data in real-time, identifying patterns, predicting potential issues, and optimising processes. Imagine an automated manufacturing system that can self-diagnose problems before they cause downtime or adjust production parameters based on real-time demand forecasts.

Real-time Insights for Continuous Improvement:

The true magic lies in the synergy between IoT and AI. The real-time data from IoT sensors empowers AI to make informed decisions that can be immediately implemented within automated manufacturing systems. This continuous feedback loop allows for constant improvement, leading to:

- Predictive maintenance: AI can predict equipment failure before it happens, preventing costly downtime and ensuring smooth operation.

- Improved process optimisation: AI can analyse production data and recommend adjustments to optimise efficiency and minimise waste.

- Enhanced product quality: By monitoring production parameters in real-time, AI can ensure consistent product quality and identify potential defects early on.

The Future of Manufacturing is Smart:

The integration of IoT and AI in smart manufacturing is revolutionising the industry. By harnessing the power of real-time insights, manufacturers can achieve unprecedented levels of efficiency, flexibility, and cost-effectiveness. As automation in manufacturing continues to evolve, AI and IoT will become the cornerstones of a smarter, more sustainable future for manufacturing.

AI in Product Design and Development:

Artificial intelligence (AI) is rapidly transforming the landscape of product design and development. This powerful technology is not only redefining how products are envisioned but also streamlining the entire development process, from concept to manufacturing. Here’s how AI is making waves in this exciting domain:

Intelligent Design Tools:

AI-powered design tools are revolutionising the initial stages of product development. These tools leverage machine learning to analyse vast amounts of data, including user preferences, material properties, and market trends. This empowers designers to generate innovative concepts, iterate on ideas faster, and optimise product functionality for a wider range of users.

Enhanced Prototyping & Testing:

AI can significantly enhance how prototypes are created and tested. AI systems can analyse user interactions with prototypes, identifying potential design flaws and areas for improvement. This allows for rapid iteration and optimisation, leading to a more refined final product.

Automation in Manufacturing:

AI is playing a crucial role in automation in manufacturing. By integrating with automated manufacturing systems, AI can optimise production lines, predict maintenance needs for equipment, and even manage inventory levels in real-time. This translates into increased efficiency, reduced downtime, and improved product quality.

AI-powered Automotive AI:

The automotive industry is a prime example of how AI is shaping product development. Automotive AI is being used to design self-driving cars, optimise engine performance, and even personalise the in-car experience for AI in driver assistance.

The Future of Collaboration:

AI acts as a bridge between designers, engineers, and manufacturers. By analysing data and identifying potential roadblocks, AI facilitates smoother collaboration throughout the entire product development process. This fosters innovation and ensures a more efficient path from concept to automated assembly line.

Overall, AI is ushering in a new era of product design and development. By leveraging its capabilities, companies can create innovative products, streamline production processes, and ultimately deliver exceptional value to their customers.

Addressing Challenges and Risks in Implementing AI in Manufacturing:

While AI presents a revolutionary force in manufacturing, its implementation comes with its own set of challenges and risks. Here’s a closer look at some key hurdles to address:

Data Quality and Integration:

Automated manufacturing systems heavily rely on accurate, clean data. Integrating data from various sources, like sensors on the automated assembly line and historical production records, is crucial for training effective AI models. However, ensuring data quality and seamless integration can be a complex task

Explainability and Transparency:

As automotive AI and other AI-powered systems make decisions on the factory floor, understanding their reasoning becomes paramount. Lack of transparency in AI algorithms can create challenges in identifying and troubleshooting issues within the automated assembly line.

Job Displacement and Workforce Training:

A major concern surrounding AI in manufacturing is the potential for job displacement. While AI is likely to automate repetitive tasks, human oversight and expertise will remain essential. Investing in retraining programs can equip the workforce with the skills needed to thrive alongside AI.

Security and Safety Considerations:

Integrating AI into complex automated manufacturing systems necessitates robust cybersecurity measures. Mitigating potential vulnerabilities and ensuring the safety of human workers alongside AI systems are crucial considerations.

Cost and Return on Investment (ROI):

Implementing AI solutions can involve significant upfront costs for hardware, software, and talent acquisition. Carefully evaluating the ROI and ensuring long-term benefits for the entire production process is essential.

By proactively addressing these challenges, manufacturers can harness the immense potential of AI. Artificial Intelligence can optimise production lines, improve quality control, and enhance efficiency within automated manufacturing systems. Embracing AI responsibly, with a focus on human-AI collaboration and a skilled workforce, paves the way for a more productive and innovative future in manufacturing.

Author Bio

Read More Blogs

AI Customer Segmentation – Connecting Customers for Targeted Engagement